A low-cost optical system for in-line automated fermentation control

Batch-Fermentationen werden traditionell bei der Herstellung von Wein und anderen Fermentationsverfahren eingesetzt und leiden unter großen Konzentrationsgradienten, die Stress für die Produktionsorganismen verursachen und den Fermentationserfolg beeinträchtigen können. Fed-batch Fermentationen adressieren diese Probleme. We demonstrated recently that a certain kind of innovative fed-batch fermentation dramatically reduces yeast stress and acetic acid formation in wine fermentations. Diese Art der Weinbereitung ist hoch innovativ und eröffnet bedeutende Möglichkeiten zur Verbesserung der Gärung und der Produktqualität. However, it requires automatic analysis of sugar concentrations in order to regulate the feeding rate. Der Antragsteller hat nachgewiesen, dass FTNIR in der Lage ist, eine kontinuierliche Inline-Analyse der Zuckerkonzentrationen während der Gärung zu liefern. This method provides the required proof-of-concept, but an alternative technology to a research grade FTNIR has to be found, since the current cost of ~50-70k for the equipment constitutes a barrier for commercial success.

For this project, we have formed an interdisciplinary research partnership composed of personnel from HES- CHANGINS and HE-ARC with expertise in industrial microbiology, automation, optical engineering and electronic processing.

The partners have identified several synergistic approaches to reduce overall system cost. These include multiplexing the liquid handling of the measurement system as well as low-cost analytical alternatives including spectrophotometic methods.

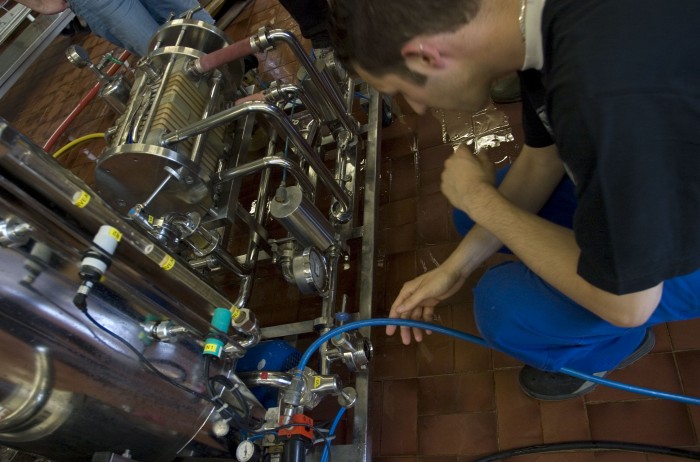

Accordingly, we propose developing and implementing a multiplexed low-cost optical system for the quantification of key parameters that allows for in-line control of grape wine fermentations under practical conditions. The project will be driven by the expertise of HES-ARC with optical hardware and the establishment of calibration models, and the know-how of HES-CHANGINS with regards to fermentations and automation technology. Given the opportunities for both optical equipment and process automation manufacturers in Switzerland, as well as for the improvement of wine quality from application of modern vinification methods, we are convinced that the current project has a high potential for success, and partnerships.

2015 - 2018

Partners: HE-ARC

Funding: HES-SO